Insertion valves play a crucial role in controlling the flow of fluids in pipelines. They are essential for industrial processes where the movement of liquids needs regulation. Insertion valves come in various forms, ranging from simple devices to complex systems with advanced technologies.

Read here to explore the different types of insertion valves and their applications in various industries. We’ll delve into the features and benefits of each type to facilitate a better understanding of these valves.

What Are Insertion Valves?

First, it’s important to understand what an insertion valve is. These devices enable the diversion or regulation of fluid flow in pipelines. You can insert them into pipelines, regardless of size, to control the flow rate, pressure, and direction of the fluid. The valves disrupt the flow of a pipeline, and you can move them to open up the line again. Some vales have sensors that measure the flow rate, level, and temperature of the fluid passing through the pipeline.

The Different Types of Insertion Valves

Now that you have a grasp on the basics, let’s cover the different types of insertion valves before exploring their potential applications.

Gate Valves

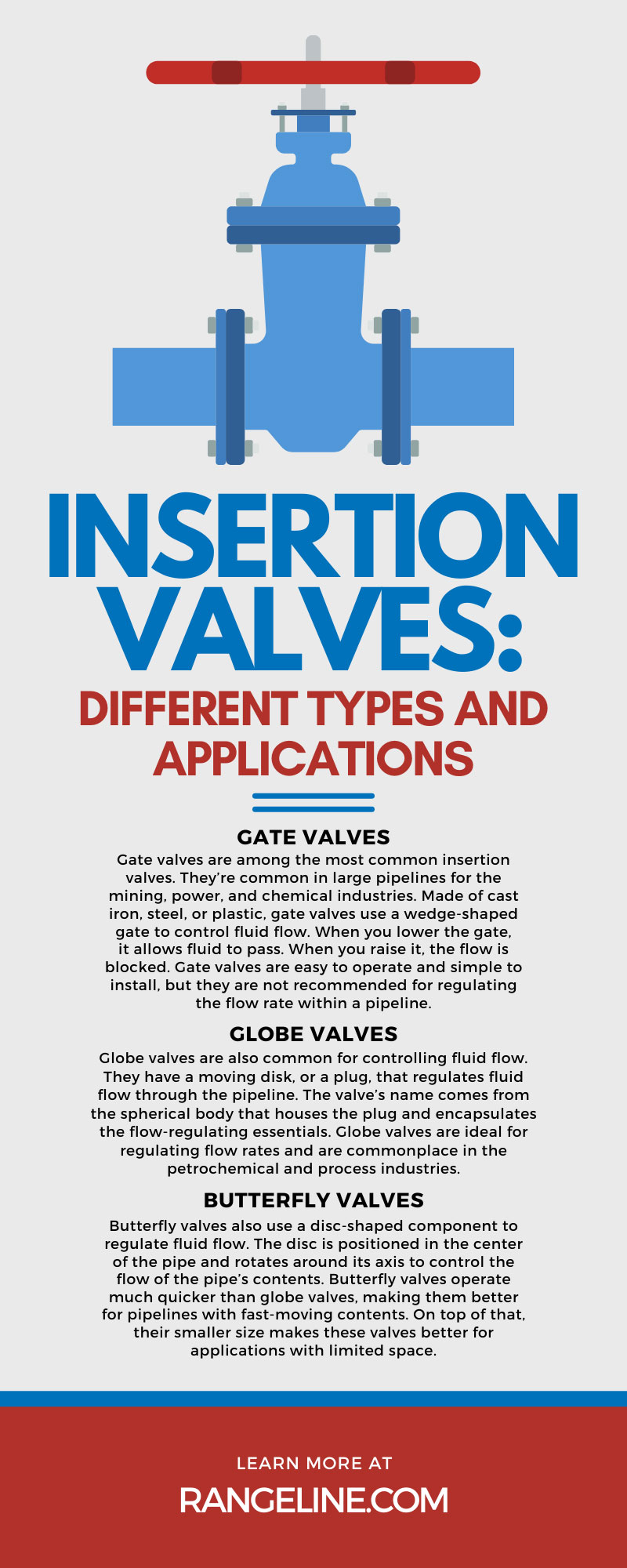

Gate valves are among the most common insertion valves. They’re common in large pipelines for the mining, power, and chemical industries. Made of cast iron, steel, or plastic, gate valves use a wedge-shaped gate to control fluid flow. When you lower the gate, it allows fluid to pass. When you raise it, the flow is blocked. Gate valves are easy to operate and simple to install, but they are not recommended for regulating the flow rate within a pipeline.

Globe Valves

Globe valves are also common for controlling fluid flow. They have a moving disk, or a plug, that regulates fluid flow through the pipeline. The valve’s name comes from the spherical body that houses the plug and encapsulates the flow-regulating essentials. Globe valves are ideal for regulating flow rates and are commonplace in the petrochemical and process industries.

Butterfly Valves

Butterfly valves also use a disc-shaped component to regulate fluid flow. The disc is positioned in the center of the pipe and rotates around its axis to control the flow of the pipe’s contents. Butterfly valves operate much quicker than globe valves, making them better for pipelines with fast-moving contents. On top of that, their smaller size makes these valves better for applications with limited space.

Check Valves

Check valves control the flow of fluid in pipelines in only one direction. They are common in water treatment plants, oil and gas platforms, and chemical processing plants that must prevent backflow. The valve design utilizes a flap or ball that permits fluid to flow in one direction. Check valves come in different designs, including swing, wafer, and lift check valves.

Ball Valves

Ball valves are another type of control valve that uses a rotating ball to regulate fluid flow. However, this ball has a hole in the middle, and when it is positioned in line with the flow of fluid, the valve opens. When the ball is rotated perpendicular to the flow of fluid, the valve closes. These valves are ideal for applications where a tight seal is required. They are also great for applications with high flow rates.

Needle Valves

Needle valves regulate low flow rate fluids and high-pressure drops. These valves control fluid flow using a tapered, sharp-pointed needle that is screwed in or out to increase or decrease the flow rate. The precision technology allows the valve to control fluid flow accurately, making it ideal for use in research laboratories and hydraulic systems.

Magnetic Flow Meter Valves

Magnetic flow meter valves are sophisticated insertion valves for food processing, water treatment, and chemical manufacturing. They use electromagnetic principles to measure the flow rate of fluids passing through pipelines. As an electrically conductive fluid flows through the valve, it generates a magnetic field that induces a voltage in electrodes on the valve’s body. The voltage is proportional to the flow rate, allowing the valve to provide accurate flow measurements.

Applications of Insertion Valves

We’ve mentioned a few industries that use insertion valves—water treatment, oil and gas, mining, chemical manufacturing, and the food and beverage industry. Some of the typical applications of insertion valves include the following:

Controlling and Regulating Flow Rates in Pipelines

This is crucial for maintaining optimal efficiency and ensuring the right volume of fluid is transported at the right time. It involves carefully adjusting valves and other mechanisms to achieve the desired flow rate, whether it’s for industrial processes or the transportation of liquids.

Preventing Backflow of Fluids in Pipelines

This is a key aspect of pipeline design and operation. Backflow can occur with a sudden change in pressure, causing fluids to flow in the opposite direction. By implementing backflow prevention mechanisms, such as check valves or backflow preventers, you can maintain the integrity of the system and prevent contamination or damage.

Measuring the Flow Rate of Fluids Through Pipelines

This is essential for process control and monitoring. Accurate flow measurement ensures the right fluid volume is being transported and allows for making any necessary adjustments. You can employ various flow measurement techniques depending on the requirements of the application.

Accurate Regulation and Control of Fluid Flow

This becomes crucial when you need precise dosages and quantities. Regulation and control are especially important in the pharmaceuticals, chemical processing, or food and beverage industries, where precise control of fluid flow is necessary for quality assurance and consistency. By employing advanced control systems and precision instruments, you can ensure that the correct volume gets delivered at the right time with minimal waste.

Adding Safety Features to Pipelines

Safety features can prevent overpressure, which may lead to system failure. Pressure relief valves, rupture discs, or pressure regulators protect the pipeline from excessive pressure buildup, ensuring the integrity and reliability of the system. These safety features play a critical role in preventing accidents and ensuring the smooth and safe operation of pipelines.

Should You Install Insertion Valves?

By now, you know how important insertion valves are in regulating fluid flow in pipelines. If you would like to add insertion valves to your pipeline, reach out to the professionals at Rangeline Group. We’ll install your valves correctly and ensure they work well.