Request Quote

Process piping contracting serves as the backbone of critical infrastructure across energy, manufacturing, and chemical processing industries. These complex systems transport fluids, gases, and materials under demanding conditions, requiring precision engineering and reliable performance. As operational demands intensify and safety standards evolve, traditional approaches to piping design, fabrication, and maintenance face mounting pressure to deliver greater efficiency and reliability.

Automation technologies are revolutionizing how contractors approach process piping projects, from initial design through long-term maintenance. Advanced materials, artificial intelligence, robotics, and digital monitoring systems are reshaping industry standards while addressing persistent challenges in cost management, safety protocols, and environmental compliance. If you want to learn more about these automation trends in process piping contracting, you’re in the right place.

Composite materials are establishing new performance benchmarks in process piping applications. These lightweight alternatives to traditional steel and metal alloys demonstrate superior resistance to corrosion while maintaining structural integrity under high-pressure conditions. Chemical processing facilities particularly benefit from composite pipes that withstand aggressive substances without degradation, extending operational lifespans and reducing replacement frequencies.

Smart materials incorporating self-healing properties represent another significant advancement. These innovative solutions automatically respond to minor damage, sealing small cracks and preventing larger failures. Sustainable material options, including bioplastics and recycled metal composites, address environmental concerns while maintaining performance standards required in industrial applications.

Taking things a step even further, nanotechnology integration enhances material capabilities through strategic nanoparticle incorporation. These microscopic additions strengthen pipe walls while reducing overall weight, creating opportunities for more efficient installation processes and reduced structural support requirements. The enhanced durability of nano-enhanced materials translates to longer service intervals and decreased maintenance costs.

It should come as no surprise that AI has become a significant part of process piping, transforming monitoring systems through the analysis of vast datasets from multiple sensors simultaneously. AI algorithms identify subtle patterns indicating potential equipment failures before visible symptoms appear, enabling proactive maintenance scheduling. This predictive capability prevents costly emergency shutdowns while optimizing operational efficiency across entire piping networks.

The Internet of Things (IoT) is also involved with the sensors that create comprehensive monitoring networks throughout piping systems. These connected devices continuously track pressure levels, temperature fluctuations, and flow rates, transmitting real-time data to centralized control systems. IoT integration enables immediate response to anomalies, significantly reducing downtime through preemptive troubleshooting and rapid issue resolution.

To add to that, drone-assisted inspections provide visual access to previously challenging locations without exposing personnel to hazardous environments. Equipped with high-resolution cameras and thermal imaging capabilities, drones conduct thorough examinations of elevated piping, confined spaces, and chemically hazardous areas. This technology delivers faster inspection cycles with superior accuracy compared to traditional manual methods.

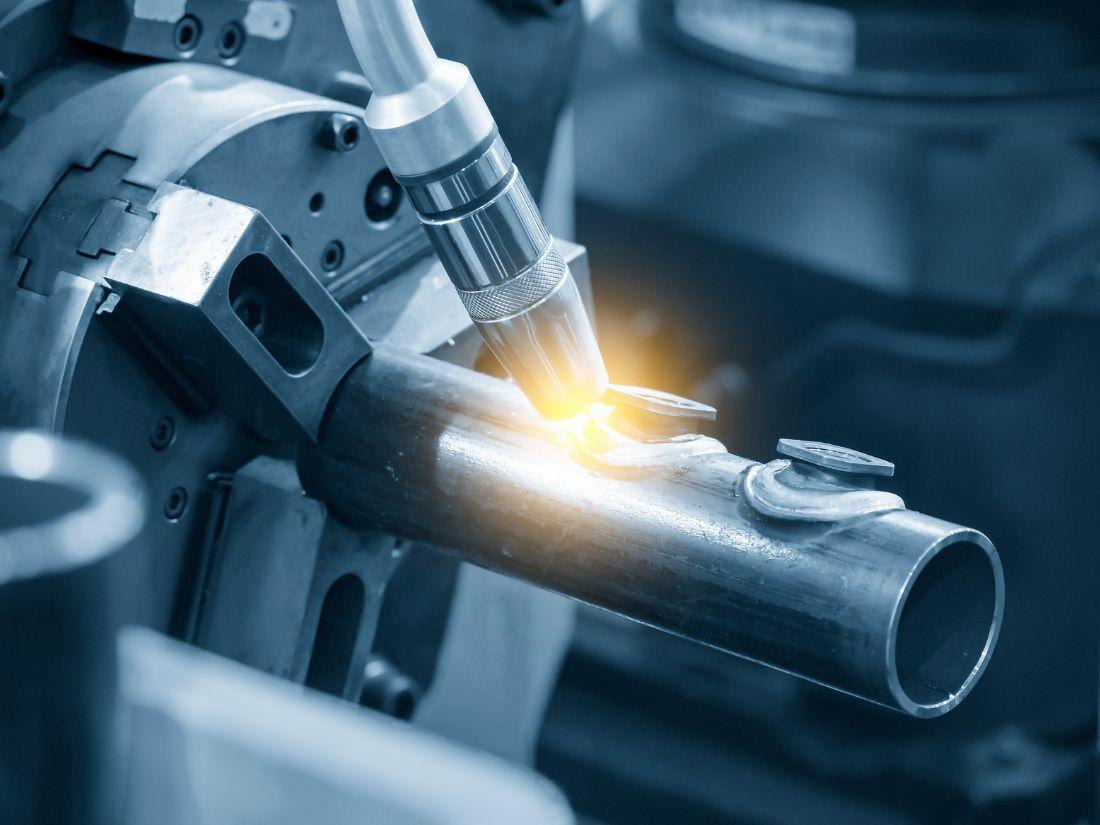

Of course, we can’t talk about automation trends in process piping contracting without going over automated welding. These systems achieve unprecedented precision in pipe joint fabrication while eliminating human error variables. Robotic welding equipment maintains consistent heat application and material deposition, producing uniform joints that exceed manual welding quality standards. This automation accelerates production schedules while enhancing worker safety by removing personnel from hazardous welding environments.

Robotics excels in repetitive fabrication tasks, meaning it can deliver consistent results across large production runs. Automated cutting, forming, and assembly operations maintain tight tolerances while operating continuously without fatigue-related quality degradation. The implementation of robotic systems significantly reduces labor costs while accelerating project completion timelines.

More advanced robotic systems adapt to varying pipe specifications through programmable parameters, accommodating custom requirements without extensive reconfiguration. This flexibility supports diverse project needs while maintaining the efficiency benefits of automated production processes.

When it comes to piping solutions, additive manufacturing enables on-demand production of complex pipe components that would be difficult or impossible to create through traditional fabrication methods. 3D printing technology produces intricate geometries, custom fittings, and specialized connectors with minimal material waste. This capability reduces inventory requirements while providing rapid prototyping for unique design challenges.

Modular piping systems manufactured in controlled offsite environments demonstrate superior quality control compared to field fabrication. Preassembled components arrive at installation sites ready for connection, dramatically reducing on-site construction time and associated labor costs. Modular approaches also minimize weather-related delays and improve overall project scheduling predictability.

Prefabricated systems undergo comprehensive testing before shipment, ensuring functionality and identifying potential issues in controlled environments rather than during critical installation phases. This quality assurance approach reduces field modifications and enhances system reliability.

Energy-efficient piping systems incorporate advanced insulation materials that significantly reduce heat loss during fluid transport. Enhanced thermal management reduces energy consumption while maintaining process temperatures within required parameters. These improvements contribute to lower operational costs and reduced environmental impact across industrial facilities.

Add to this integrated water recycling systems within process piping networks that support sustainable operations by capturing and reprocessing wastewater streams. These closed-loop designs minimize freshwater consumption while reducing waste discharge volumes, addressing both environmental concerns and regulatory compliance requirements.

Don’t forget that environmental regulation compliance drives adoption of materials and installation practices that minimize ecological impact. Automated compliance monitoring systems track environmental metrics and generate required documentation, ensuring adherence to evolving regulatory standards while reducing administrative burden.

Outside of the piping process, augmented and virtual reality platforms provide immersive training experiences for piping system operators and maintenance personnel. These technologies enable hands-on practice with complex procedures in safe virtual environments, improving skill development while reducing training costs and safety risks associated with live system training.

Contractors also use digital twin technology to create virtual replicas of piping systems that mirror real-world performance characteristics. These digital models enable predictive simulations, design optimization, and performance testing before physical installation. Digital twins identify potential design flaws and operational inefficiencies during planning phases, preventing costly modifications after construction.

Most importantly, though, many process piping contractors use data-driven maintenance strategies to analyze historical performance data alongside real-time monitoring information to forecast equipment maintenance needs accurately. This analytical approach extends system lifespans while reducing emergency repair incidents through proactive component replacement and system optimization.

Automated compliance software solutions streamline record-keeping and regulatory reporting processes. These systems maintain comprehensive documentation of inspections, maintenance activities, and system modifications, ensuring consistent adherence to industry standards while minimizing legal compliance risks and administrative overhead.