Advancements in the line stopping process are enabling those with extensive pipeline networks to perform maintenance and repairs with greater efficiency, safety, and precision. Since there’s a lot to know […]

Read MoreRequest Quote

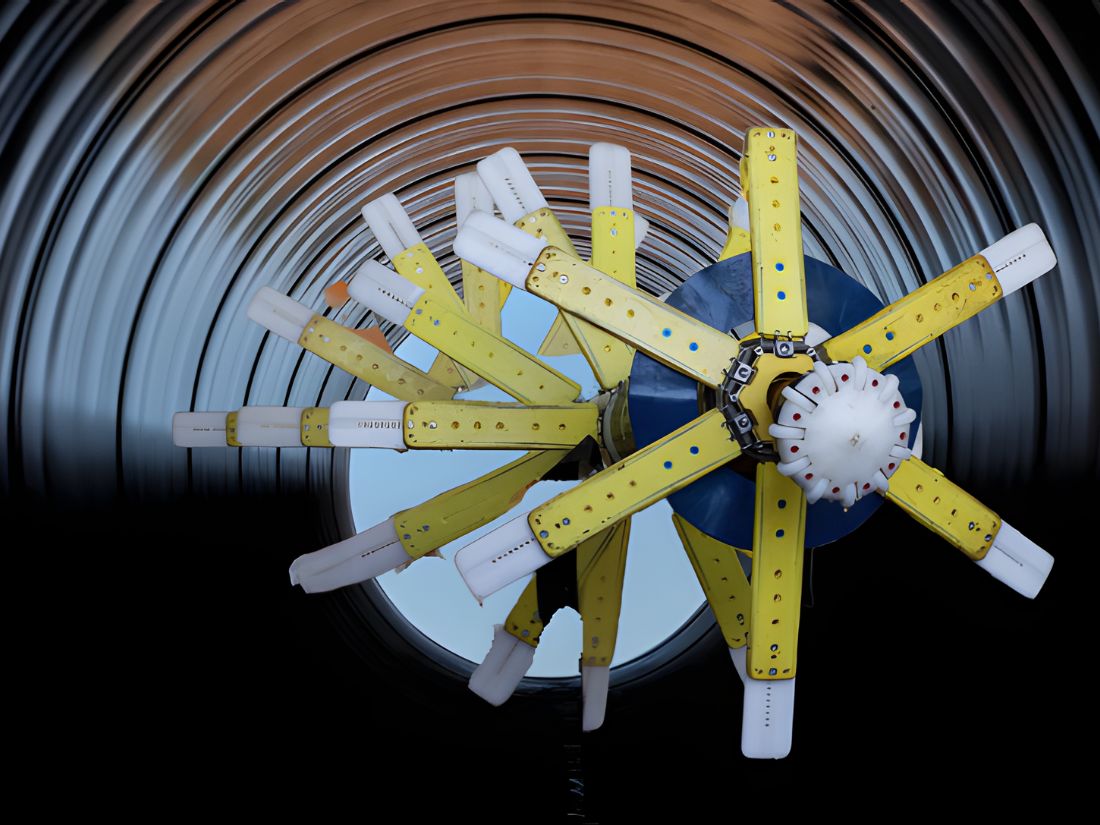

This detailed animation illustrates how a pipe break on a working pipeline system is resolved by a line stop. The animation demonstrates how Rangeline Group isolates pipe breaks while keeping the rest of the pipeline system up and running to mitigate downtime or loss of product.

Line stops are essential to resolving emergency breaks and can be applied to a wide variety of pipelines, including ductile/cast iron, steel, PVC, asbestos cement, concrete pressure pipes, HDPE, copper and more. Line stops are applicable in industries like municipal, industrial, and other piping systems that can’t be shut down.

For over 30 years Rangeline Group has been serving the water and wastewater industry providing safe cost-effective pipeline services, including emergency line stopping, valve inserting, tapping and much more without interrupting the product flow or shutting down the piping systems. We offer our services across the United States in an array of industries, including power plants, municipalities, manufacturing, hospitals, water distribution, and wastewater management to name a few. Let our expert team of pipeline contractors and service technicians provide the experience and expertise to make your next project a success.

At Rangeline Group we understand how important it is to grow your knowledge, not only for yourself, but for your company. This is why we offer Lunch and Learns where our team of experts come out to educate about a variety of subjects within the pipeline water and wastewater industry. Visit our contact page to schedule your lunch and learn today!

Advancements in the line stopping process are enabling those with extensive pipeline networks to perform maintenance and repairs with greater efficiency, safety, and precision. Since there’s a lot to know […]

Read More

Industries ranging from manufacturing to energy production rely on process piping systems. These systems are designed to transport fluids and gases effectively, ensuring safe and efficient operations. However, while traditional […]

Read More

Inspections are critical for maintaining pipeline infrastructure. Traditionally, these processes relied on manual methods, including visual assessments and basic flow monitoring. While effective in some cases, they lacked precision and […]

Read More

Hot tapping, a process for attaching connections to existing pipelines without shutting them down, has revolutionized pipeline maintenance and modifications. While it eliminates the need for service interruptions, some things […]

Read More