Concrete Pipeline Services

Rangeline Pipeline Services division is the latest addition to the Rangeline Group. The concrete pipeline service division is a team of experts specializing in all aspects of concrete pressure pipe. Concrete pipes are some of the strongest pipes available in comparison to flexible pipe, but many of these pipes begin to degrade as they get older. Our experienced concrete pipeline contractors will ensure that your concrete pipes are repaired and refurbished to ensure no extensive damage occurs to your business or municipality.

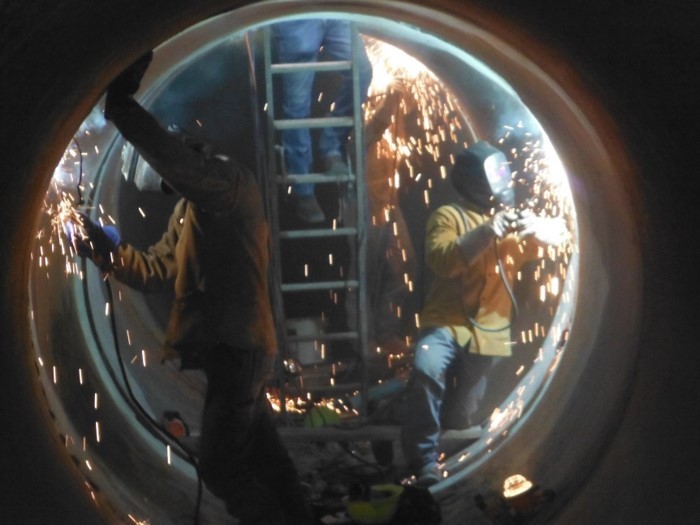

Concrete pipeline services help owners of concrete pressure systems stay current with their aging piping systems. Services include a “Valve Replacement Program”, Emergency Valve Replacement & Main Line Repairs with “on staff” welders. This is in addition to our Wet Tapping, Line Stopping and Valve Insertion Services which Rangeline Tapping has been performing for over 30 years.

Even though concrete pipelines need maintenance and repairs, we understand that a disruption in service can be detrimental. Rest assured that our services won’t be intrusive to daily life and operations either, as line stopping works to reroute the flow of energy and other resources while the affected concrete pipes are isolated and safely worked on.

Rangeline also offers a complete line of materials for concrete pressure pipe. These materials consist of MJPE Adapters, Flange Adapters, Bolt-On Repair Bands, Butt Straps and Weld-On Repair Clamps and Sleeves. We also have a team of technicians and welders to install and repair your piping systems 24 hours a day 365 day per year. Make one call to get all the help you need. Rangeline is a trusted and reliable service that will act swiftly and provide quality care nationwide. Contact us today for concrete pipeline services like installation or repairs for your business or municipality.

To learn more about Rangeline and Pipeline Services call 888-PCCP-HLP today!

Concrete Pressure Pipe Services

Common PCCP Repair Solutions

Joint Leaks – Three Main Causes

Scheduled Valve Replacement

MJPE Adapters and Butt Straps

Full Pipe Length Replacement

Transitioning Multiply Products to Satisfy Customers Needs DI, PVC & PCCP